Difference between electrolytic copper and cathode copper

There is no difference between electrolytic copper and cathode copper.

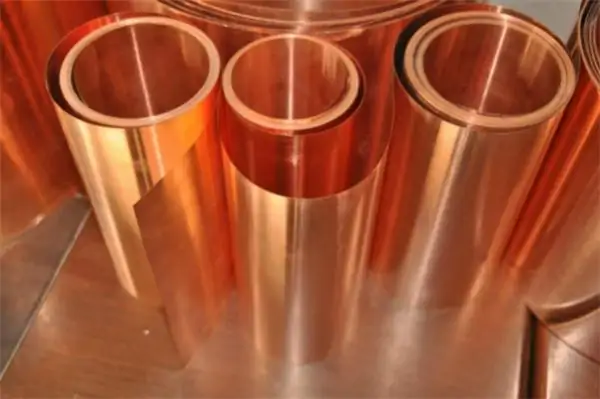

Cathode copper generally refers to electrolytic copper, which refers to the prefabricated thick copper plate (containing 99% copper) as the anode, the pure copper sheet as the cathode, and the mixture of sulfuric acid and copper sulfate as the cathode. electrolyte.

After electrification, copper dissolves from the anode into copper ions (Cu) and moves to the cathode. After reaching the cathode, electrons are obtained, and pure copper (also called electrolytic copper) is precipitated from the cathode. Impurities in crude copper, such as iron and zinc, which are more active than copper, will dissolve with copper into ions (Zn and Fe).

Because these ions are more difficult to precipitate than copper ions, as long as the potential difference is properly adjusted during the electrolysis process, the precipitation of these ions on the cathode can be avoided. Impurities that are more active than copper, such as gold and silver, are deposited at the bottom of the electrolytic cell. The copper plate produced in this way, called “electrolytic copper”, is of high quality and can be used to make electrical products.

Uses of electrolytic copper (cathode copper)

1. Electrolytic copper (cathode copper) is a nonferrous metal closely related to human beings. It is widely used in electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields. The consumption of aluminum materials in China is only second to that of non-ferrous metal materials.

2. In the manufacturing of machinery and transport vehicles, it is used to manufacture industrial valves and accessories, instruments, sliding bearings, molds, heat exchangers and pumps.

3. It is widely used in the manufacturing of vacuum cleaners, distillation tanks, brewing tanks, etc. in the chemical industry.

4. Construction industry is used for various pipes, pipe fittings, decorative appliances, etc.